waffle.gh (37.5 KB)

Hi all, I am struggle and i need some help in continuing the waffle structure script for laser cutting and create solid union after extrude command. I have to created waffle structure and need to laser cut it, what i have now is a script of waffle structure but the “brep” and solid union and intersection ribs for connecting two structure doesnt work. Can anyone please help to have a look with what went wrong in the script attached here? or did i not creating the script correctly. Thanks!

DUPLICATE THREADS ![]()

![]()

Dear Hins,

Yes, sure we can help, but you will probably not be happy with, with my answer now. Being able to help you, it start with you helping us, so we understand what you want, what you need and find some answers:

- As @Joseph_Oster made very clear: you have now two times the same topic. Maybe caused while deciding in what category it should be. One two much. So choose 1 and set it to all categories you want.

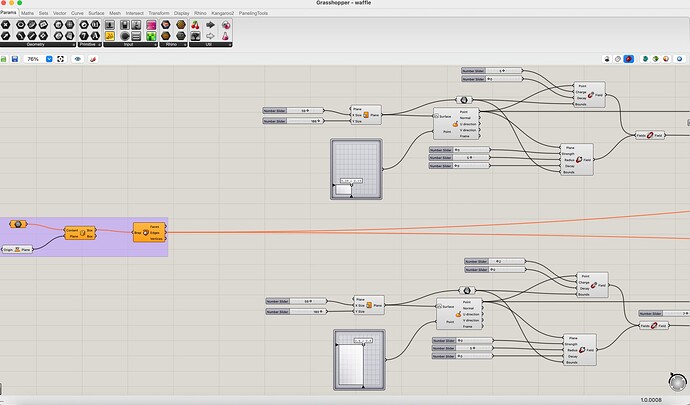

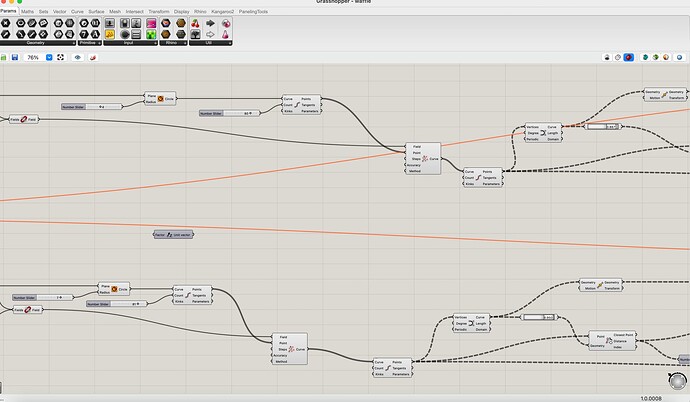

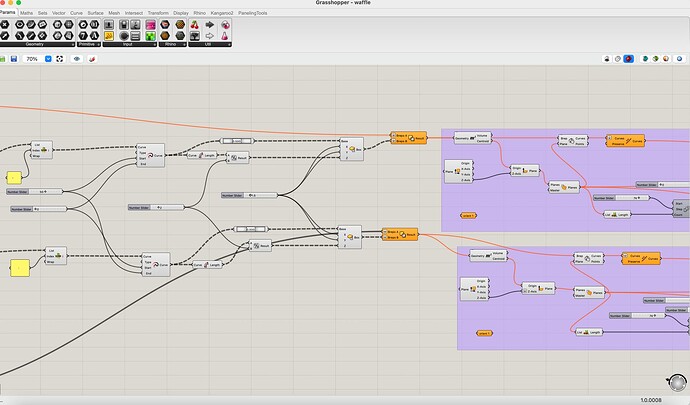

- I put about 10-15 minutes of reading/studying on your file now, and have no clue how it is setup. So second advise: If you want others to help, present it in such a way that they can find the way in what you did. Work from left to right (what you already did

). Group stuff what belongs to eachother, place subscriptions on what it is (so use Add Group; Label or Scribble to explain what it is).

). Group stuff what belongs to eachother, place subscriptions on what it is (so use Add Group; Label or Scribble to explain what it is). - Now the most important: read/study the first two sticky topics in the forum about how to ask your questions. For us very important that you just send a small part of your file.

- Find the spot with the trouble

- Isolate it, by adding geo, num , curve etcetera components and internalise only what is needed.

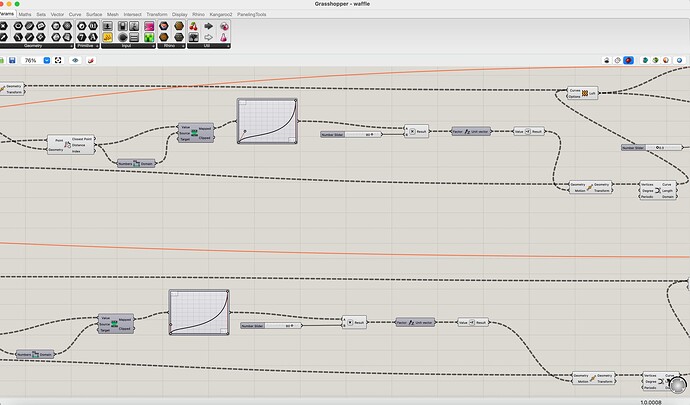

Because for what I understand somewhere in your file is a spot with a problem where Solid Union is not working.

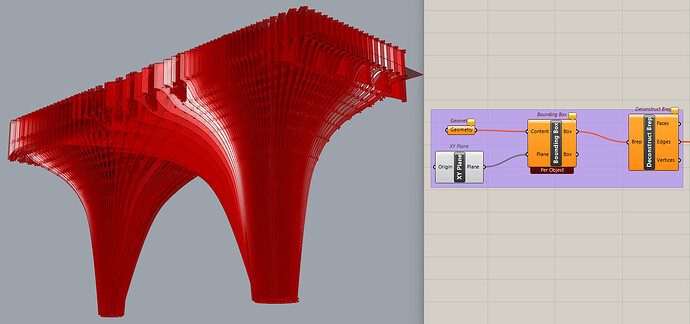

There I see that you try to combine 80 closed breps into 1 brep. That is going to be a hard job. Because when you have two closed breps (we don’t talk about 80 yet), is can already be hard to join them, because of small issues in geometry. The more complex it gets, the harder it will be.

So my suggestion:

- take a step back

- first build a small part with just as tiny part. When you got that working OK. study how to make it bigger.

- And my guess is, that getting 80 breps to join, is going to be very very hard,

Think about simpler solutions.

Good luck, and hope to see your answer and smaller question soon.

Regards, Eef

I didn’t even look at your GH file, in part because of duplicate threads and in part because all your images are of the code (the GH file is WAY BETTER for that!) and none of the geometry.

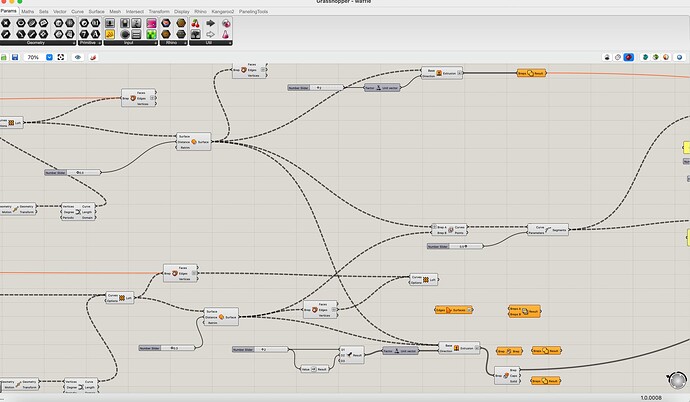

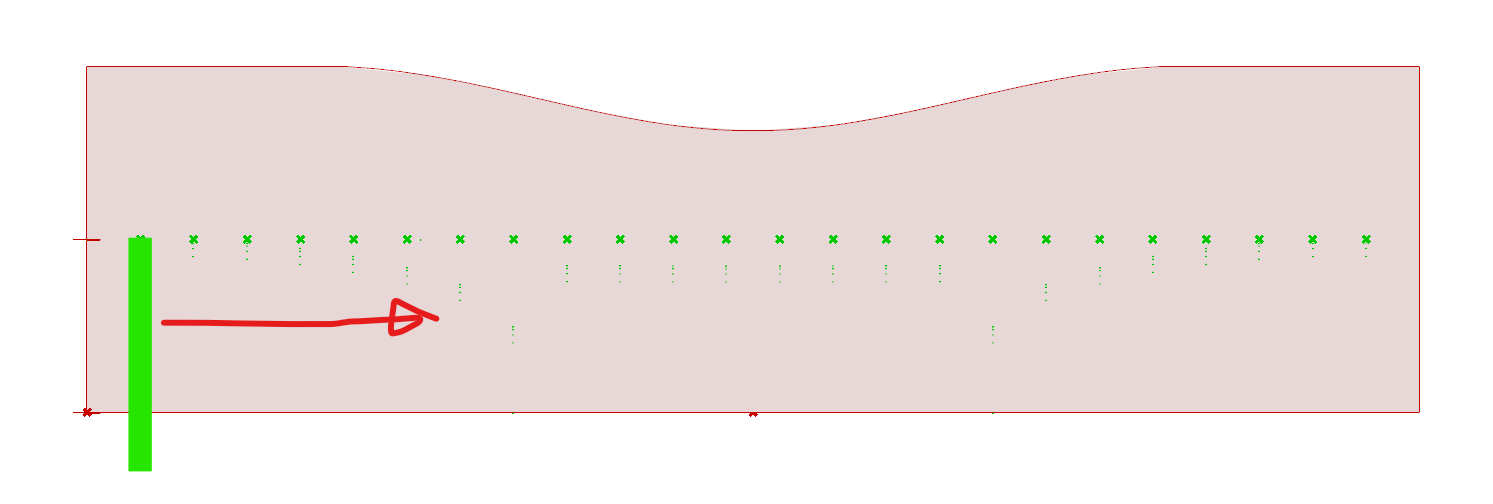

When I finally looked, the first thing I see is missing geometry (orange components and wires).

Looks like the same thing is in your images of the GH code? ![]()

The structure is complex, did you search the forum for “waffle” and study the many examples? As always, I think it’s best to reduce the number of pieces (80 ![]() ) until you know it works before increasing the count.

) until you know it works before increasing the count.

Am I correct you are trying to make something like the guy in the video?

Waffle Structure

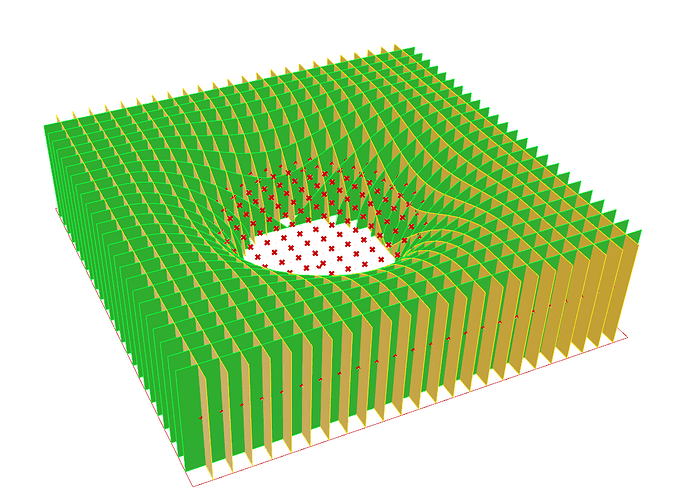

There are many people here that can solve problems, but you must describe so we understand. Instead of all the images of your script that add little to describing the problem start by explaining the basics of whatever this is. It seems like there is a surface that drives the shape, and ribs in two direction. The ribs have half joints so they fit together. I assume the ribs are orthogonal so you can make simple cuts.

I doubt many understand what is meant by waffle structure. In my work this would be something very different.

It seems both myself and the OP need to use the search. ![]()

Now that I searched I see a great number of waffle threads. I see most are modelling the ribs as solids. Is there a benefit to that? I assume most are using thin stock, so that must add some calculation time? I mocked up a simple example out of interest and it seems to be a solvable problem using surfaces. Then again, I did not complete the project. Engraving part numbers would sure seem helpful if the parts get large.

How do you know the width of slots without thickness? Or does your code ignore them? Half depth slots is a major part of waffle structures.

I would find the intersection points and then place a cut using the orient. The cut width would be controlled by width input. The height of the cut would extend thru the parts top and bottom. After I have those I could cut the original parts.

This is a close-up of the interlocking slots, from Waffling_Troubles_2019Nov24c.gh.

I understand how it is assembled. I made a lot of RC planes growing up. It looks like I could place a shape that extends thru the part and then cut the original part in 2D. The cut is oriented up/down for the two directions. Maybe I will finish the steps in my mind at some point.

OP seems to have 2 radial grids (one for each column) crashing together so this is not a trivial waffle / grid condition where the slotting members are orthogonal to each other.

Since it also sounds like OP wants to laser cut these elements all the slots will need to be wider and unique to capture all the intersection angles.

Sounds like a far fancier laser cutter than I have worked with.

It’s not a fancy cutter, it’s a fancy GH definition! You would need to oversize the width of the slots to achieve the desired intersection angle while taking into account the thickness of the material.

Also, this is a waffle structure (presumably made of chipboard cut on a laser cutter) on a radial grid but at least the intersecting slots are still orthogonal.

How to Make this waffle? - Grasshopper - McNeel Forum

This is (now) a classic architecture school digital fabrication 101 project, but OP has gone straight to difficultly level 11.

Ok, thanks for that. I immediately thought it might be a laser other than 3 axis. I know they exist, but I have not seen them in person.

The difficultly level some start with always seems a bit much when you do not understand trees well.