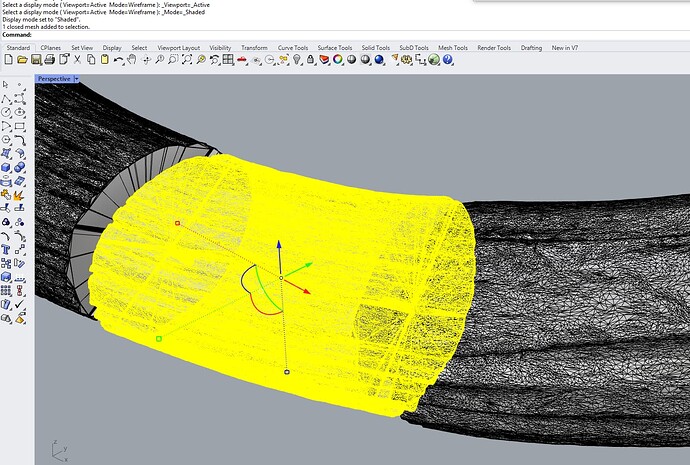

Does anyone have any advice for splitting a mesh into smaller parts for printing? I want to split this large mesh, at the planes shown, into smaller ones that can fit on my 3d printer…

Mesh booleans seem to work best where one would create a mesh box to use in a Boolean Difference operation so I could have a mesh box between each consecutive pair of planes and do a Boolean Difference for each box.

It feels like there should be an easier way though? Splitting the mesh with the planes would then leave open ended meshes that would need planar caps adding to close them.

Ultimately, I want to be able to add dowels between each smaller mesh to align them and assemble them.

The Slicer software (and other mesh processing software) can do this sort of thing but I’d like to be able to do it in GH where I have more control of the positions of the split planes.

Any advice or knowledge to share?

The Mesh is from https://www.thingiverse.com/thing:2772592 but I have simplified it using the awesome QuadRemesher for this example.

SplitMeshFor3DPrint.gh (911.8 KB)

1 Like

Thank you for your reply!

When you look close at what happens when you split a mesh like that, you can see where it creates some more challenges…

Each mesh is open and needs closing with planar faces at each end, and the split ends are not clean so even if I could create a planar end cap the mesh would probably not be closed, manifold etc.

I tried the approach of using solids and MeshIntersect which worked for the low poly mesh but fails for the high res version of this mesh for reasons I have not figured out yet.

Just need to figure out the dowels (should be no problem) and then work out why the high res mesh fails.

SplitMeshFor3DPrint_SOLIDS.gh (918.4 KB)

It seems like such a simple thing to do… split the mesh into smaller meshes with dowel holes to locate the parts for assembly after 3d printing… It’s a plugin I would happily pay for if it worked!

here the meshes are closed, do not know if it works with high res meshes.

Meshes are not that nice to work with. The risk of errors is quite high.

SplitMeshFor3DPrint.gh (922.7 KB)

Instead of splitting the mesh, I think I would rather use Mesh Difference and subtract very thin boxes and at least one cylinder per plane. The cylinder is later used to reinforce the joint with a threaded rod.

SplitMeshFor3DPrint.gh (894.6 KB)

PS: Your quad remesh had two internal voids. I deleted them.

2 Likes

That did work on the high res mesh but the split meshes were not closed. The 3d printer seems happy with a test print though!

Nice! Thanks!

This created closed meshes on the high res mesh too! I will add 3 x 8mm cylinders per join for dowels instead of threaded rod because… superglue!

Yes, the QuadRemesh created internal voids… The original mesh is an 89Mb 3D scan of a 250m year old fossilised bison skull so the fact QuadRemesh managed to create anything is mind blowing, I’ll forgive it for the weird internal voids!

1 Like