I don’t get it. Why is all the intentional unfair bashing of Rhino’s tools by the guy behind xNURBS plug-in? xNURBS is a very nice multi-sided patch tool, but I’m not sure that using bad input geometry on purpose to show how Rhino’s surfacing tools will produce also bad output geometry is a honest way to promote that plug-in and show how good is it. The majority of examples that the xNURBS team or the person behind if posted over the past few years clearly have many imperfections, despite the narrative that promises superior quality.

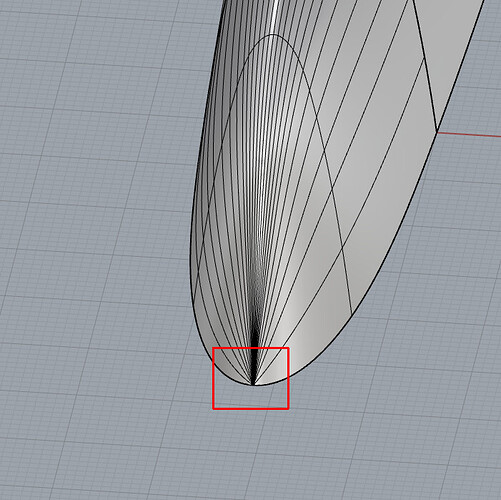

Take this video, for example. It shows a bunch of low quality curves populated with an unnecessary amount of control points placed at random locations to make the modeling more difficult.

We are having a nice civilized conversation with the gentleman on YouTube under this particular video and he is yet to answer why the geometry in his videos is always setup to perform very badly with Rhino’s surfacing tools prior capturing the videos where xNURBS is eventually shown as the proper solution for these fabricated “difficult cases”. He also tends to compare xNURBS with “Network surface”, which is not a correct way for comparisons, because the latter uses approximation of the input geometry, heavily depends on the user’s settings (which he never does and just clicks the “OK” button) and is widely known as the least good surface tool in Rhino. He also makes some quick comparisons with the “Sweep 2 rails” tool, but again, all he does is to immediately click on the “OK” button with the defaults settings, rather than trying some proper settings prior that. Again, xNURBS is a great tool, but I think that it’s unfair to use such fabricated tactics. I know that it’s a business and companies or sales individuals why try hard to present their products as the best of the best, but at the end of the day, there must be some degree of honesty. It’s like taking a Ferrari on an off-road trip and claiming “That car performs really badly on that rough surface”.

Over the past few years, there have been multiple posts regarding xNURBS on this forum and various people asked why xNURBS failed in certain easy situations. The majority of answers they received was just “You don’t use xNURBS properly”, plus some bad language at times, even though the plug-in simply failed due to imperfections in its core coding. I remember at least 3 examples where I proved to that gentleman that Rhino’s default tools perform better than his xNURBS plug-in, but the answers ware mostly some bad language. While it has its strengths, it’s not as universal as advertised, not it’s capable to produce good quality most of the time.

I downloaded the trial version of xNURBS and after a day of usage I have to say that it’s a relatively good patch tool, but it’s capabilities are far from perfect. It produces wavy surfaces even on 4-sided cases with the “Optimized for quad-sided surface” option and all the other settings for quality and precision used properly and tried in every possible combination. I think that it would be far better for this developer to be slightly more fair regarding Rhino and its excellent tools that sometimes perform much better than xNURBS. xNURBS is basically what the “Patch surface” tool in Rhino should have been in the first hand.

Don’t get me wrong, my intention is not to tell bad things about the developer. I just express my honest opinion about his intentional bashing of Rhino’s tools to make xNURBS appear the definitive choice in comparison.

McNeel has a couple of very smart people, if they would rip apart that pitiful patch just for a couple of weeks Rhino would be Master of Surfaces soon™ i bravely assume. SubD is a good amendment but Nurbs will not cease, and need some love either.

McNeel has a couple of very smart people, if they would rip apart that pitiful patch just for a couple of weeks Rhino would be Master of Surfaces soon™ i bravely assume. SubD is a good amendment but Nurbs will not cease, and need some love either.

Please, both sides, rage is not helpfull here, pull the handbrake, no accusations and back to the pragmatic discussion.

Please, both sides, rage is not helpfull here, pull the handbrake, no accusations and back to the pragmatic discussion.