What an awesome work!

I feel like such an underachiever.

Thanks! I think that it is a matter of some time to learn more about the specifics of the Rhino tools and NURBS modeling in general. Years ago, my earlier Rhino models were very basic, and I thought that I would never be able to reach the level of other people whose work impressed me at the time.

NURBS modeling is one of those things that can never be fully mastered. It is a constant process for finding a solution through trial and error that takes plenty of time and patience, because every shape requires a different approach that may not work for another shape.

If you think you fully mastered Nurbs modeling, than you are doing it wrong!

The worst thing one could do is to think that he or she is perfect. Even the true perfection is flawed, because it does not leave a room for improvement.

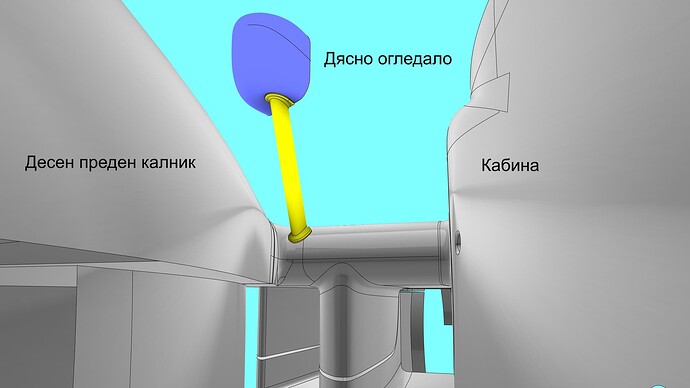

The side mirrors are ready since months, but I totally forgot to post updates here. ![]() I used various photos and a couple of videos as a reference to make them as accurate as possible.

I used various photos and a couple of videos as a reference to make them as accurate as possible.

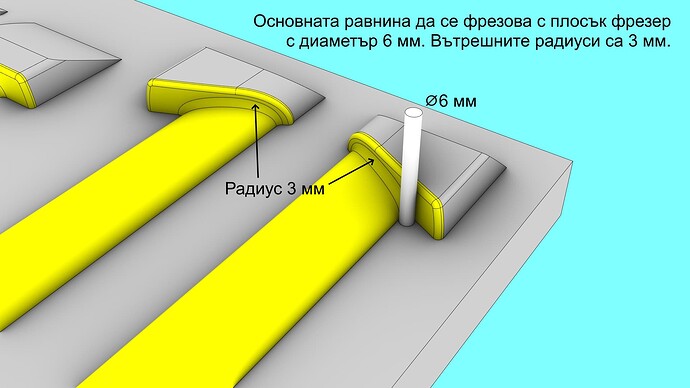

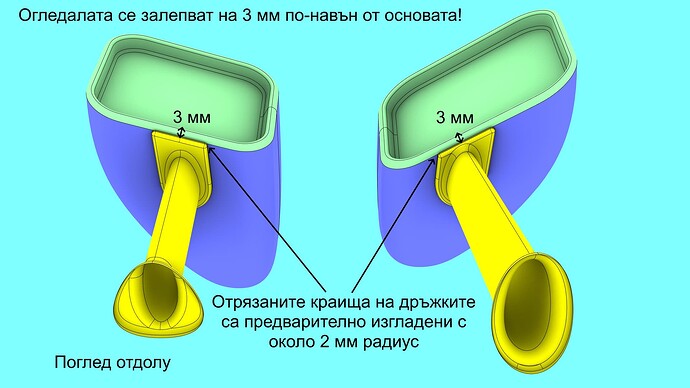

The CNC-milling, subsequent trimming and assembly required lots of steps:

Some photos of the final product. The round tip of the side mirrors was supposed to be like a ball shape, but the person who was in charge with grinding the foam plugs removed more material than necessary, hence the tips are a bit flat now…

The custom made bell housing (previously shown in the topic) was also manufactured and is currently installed on the demo car:

awesome project!