I am very interested in seeing your RhinoCAM and CNC pictures, and in understanding your approach to workpiece holding, indexing and the machining of this project. I am a professional guitarmaker, and work extensively with CNC routers in a production environment.

I will be honored!

So the first CNC test I had to do was the neck cavity fitting.

I build this quick and dirty model with the neck’s body that intersects a wood block. My Telecaster plans say the width of the neck should be 55.1 but this neck that will go on the first guitar is 56mm. So I had to add a scale width to 56.00 mms to test.

Then a roughing and two finish CAM jobs.

So here’s the tool path in the block. The G54 is set at the top middle of the guitar body.

I got really lucky that the very first try was perfect. The taper along the lengths of the neck also fits perfectly (my biggest fear).

There was no taper in the neck Z directions on the side walls but in case it was a thing, I added it to the GH model.

And here is the result, 6 minutes carving… at 2400mm/min. 20Krpm.

.Absolutely zero play between the walls and you don’t have to force or push too hard on the neck for it to fit. Removing the neck was actually harder!

Next is the neck screw placements… These are not standard… Well, one of them is not where it’s supposed to be… This means a bit of changes to the body later when the rest fits… Still unsure how to measure this correctly…

Our workshop is a production environment but I recommend that you consider this approach even if you will work on a custom project basis.

Every machine table in our shop is drilled with a set pattern of index holes. These holes are also drilled in our tooling. So when we create a model of our fixtures we model them referenced to the table index holes.

Tooling fixtures will also always have another set of holes for indexing our workpieces. These holes vary a lot in size, depth and location depending on the part we will machine.

The first step when we make something is to drill the work so it can be located. In the case of your guitar body I would probably use a hole under the neck plate and in an area that will later be routed away for a back pocket. If this is not practical I would add a small extra bit of wood on each side of the waist area to be cut away later.

index system.3dm (3.4 MB)

Thanks Abraham,

Thanks for sharing your setup.

This is indeed my plan where for each part to be carved will have a designated placement area referenced at the bottom x and mid y of my cnc bed. My current waste board is a bit used for anything at the moment but I will swap it for a new one when needed.

I will do the 4 corner holes first to plane the board both sides, then cut the two middle holes which will be used as the reference for flipping. Later on I will have a dedicated waste board for this. As well for the neck and fret board later.

I still need to test each pickup, bridge, screw cavities in this setup before I can comit to do the body. My client’s neck is ready made so that will speed up the first build a lot. But I will do a guitar for myself later.

Really appreciate any insights!

Nudge, nudge… : )

Rule of 18, actually…

Way back when I positioned frets in…waitforit…DesignCad basic. : )

Which was about 1991.

“Comparatively pretty limited” ?

Hey! You designed a pretty good damn guitar. I bought one. One day, I hope to get the one of the 22-fret American Pathfinder’s. A photographer who used to photograph everyone in town, did this (of me, some years ago)

Thanks Brenda, great photo!

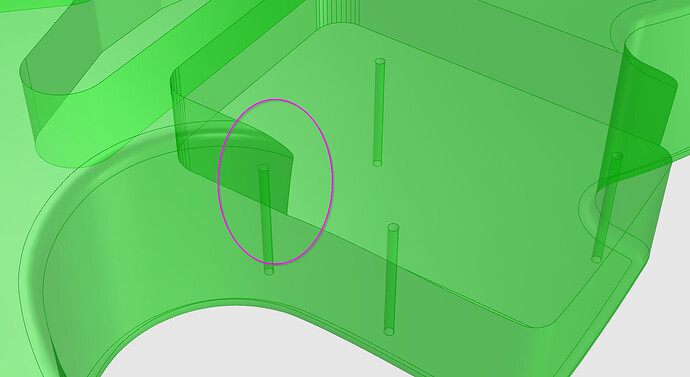

Today I learned a LOT in 1 hour… Redo each problem module until you find the cause of the problem. The body neck cavity was with issues… And it doesn’t show the bow in the supposed to be strait curve that follows…

5 days of searching for that thorny issue - this kind of helped but I wasn’t expecting this - Workflow analysis since 3-4 days. Never give up! After all this is the nature of the beast (modular guitars) and one body doesn’t fit all necks is the lesson learned!

Version 1.6.2!

- Finally found the issues with separating the bottom place from the screw holes - silly part where common tools wouldnt work… Explode and cull the wrong parts helped! Twisted solution that wont work if i change the body at any stage!

- fixed the wrong angle issue in body-neck interface. Body was not sized up (by 1.0009) like the factor of change between the new neck Y size (56 instead of 55mm) - body curves were not adjusted for this and it created a gap/undulation and an angled wall with the body. This was tortuous to find jumping between the neck group, the guitar body shaper, and duely documenting this issue once you introduce a new part into the model!

So here is the final shape!

CNC tests are next!

2nd test went ultra well! The distances are much better now but the pick-guard might come into play - not that Im going to use that ska theme one for this guitar, I have a custom job in mind. Yes, there’s a pick-guard corner in the GH model - still needs screw modeling! Thanks for reminding me!

The pickups also fit in although one needed some sanding action to fit a corner without squeezing the cables.

Drilling - more challenging than I thought at first - CAM quirks mostly… Long story short, it’s coming Saturday.

Then comes the full body carving!

So finally got down to the drilling with the CNC.

Perfect match! This makes life so much easier compared to the pressdrill options!

So after many issues with post processor not delivering the right gcode drilling (worked for standard drilling but not sequential (do 3mms, retract, go 6mms, etc)…

Solved thanks to the awesome support from RhinoCAM. I have finally made at least 20+ drill holes in the perfect position. Super happy.

I measured the nut’s distance to the bridge’s and WOW - it’s perfect! Wasn’t expecting perfect position at the first time from this old 50’s plan since the pickups were not in the right place. But now all fits perfectly after I assembling the neck of the guitar and the cavity in body.

Neck holes for the screws that hold on the neck to the guitar body are a bit off… Still by .5mms here and 1-2mms there… Trying to make an accurate gauge/template to find the right pattern… Took 1 week but finally realized I have transparent plexiglass sheets to do this with! And I rewrote the module that was just overly complicated.

Thanks to Diff-Arch for showing me the GH way (side joke, I didn’t use planes much in this model. But it soon becomes an apparent need converting my older code following the measurements in this paper plan model to a 3D model (in GH)… ![]()

So now Im trying to resolve the baking issue…

Each time I bake a new part I need to redefine it’s geometry in RhinoCAM.

Finally Im working now on the “primordial block” (pun to the guitar taoists among you).

But I got to work on the reference surface before I get to that… It’s a 3-2-1 step approach. With my usual cnc stuff, i just cut and see. Here, I have to make sure it fits before I cut!

First issue I found with my previous approach is that my screw positions for flipping depend on the distance to the edge of the block. Not that of the “waste board” reference. So, a new step/level/layer/etc incoming…

I recently made a parametric fingerboard generator in grasshopper, you might it useful for this project:

https://morgankelsey.com/articles/rhino-parametric-fretboard-generator/

Nice, I will check it out!!!

Completely reinstalled my PC, Rhino7 and 8 + rhinocam + GH plugins… 7 months HW build, however OS was reused carelessly ![]() LOL - I just dropped the M2 NVM .5TB drive on the new mobo and it worked? WTF? That is SLICK like Mick Jaegger!!!

LOL - I just dropped the M2 NVM .5TB drive on the new mobo and it worked? WTF? That is SLICK like Mick Jaegger!!!

Creative writing flashback time…

I was a long time fan of MacOS, just plug-in a SCSI drive on a Mac, reboot and copy the OS/last backup and voila - done in 30 minutes! Back to yesterday including all apps and preferences! Magic restore! This was never ever the case for windows since ever. Any new HW = new reinstall - loose your settings - Im surprised how Windows OS has recovered - unless you dont have access to a cloud at the reinstall moment… Good luck!

Since I work Pro on PCs only (gave up Mac after 9.0-osx transition requiring BMW priced HW each time… ) - the usual customer was annoying architects and doctors, the other was paying customers… I loved working with offset printers and publishers!

End of flashback -

LPT: bsod is like a mac-crash! Lost more time figuring out the issue than just reinstalling the OS/apps.

LPT: save as often as you think cmd-s or ctrl-s!

LPT: keep a change history!!! Track the progress too on a calendar basis.

Had a BSOD (windoze thing) from either one of 4 RAM modules or my M2 boot drive. And it was both… 6 weeks trying to get this fixed took some bold actions which took 1 week to finish with non-enterprise backup means. Including compressor air clean up of the PC…

Im at 164 new versions of the original project - for grasshopper only, 18 different versions of the 3DM file. A year almost time programming this thing that should take about 30 minutes max to carve in CNC time (exluding tool changer time - manual right now…)…

I’ve done about 6 different tests of shape and cavity carving. Screw positions etc. Lots of side adjusting for each new version to make sure all external parts such as neck, pickups, bridge and dimensions are up to spec. (distance from the nut included).

Almost time to carve the full body! I keep saying that…

So working on the latest versions… made lots of improvements… since I last posted…

Found a nice way to show the neck (not the pickups yet…).

Lots of new steps to mill each part. Different depth pockets and the option to use the same mill for most of the body top makes that easy.

Ball mil for the body contour (a new pain to work with because I found a bad curve from an interpolation that makes the lofting impossibly complicated. Im building the case GH file to show it so maybe someone can solve it…)

I dont have an automatic tool changer on my CNC so each tool change (1 compression 6mm flat mill, 1 3mm drill (which will change in the future…) takes time as well as resetting the Z0 reference position of the mill’s bottom end. Could be automated with a tool sensor but Im insecure about this still… But it’s become a monster CNC project compared to what I had in mind a year ago. Doing the testing I learned how the center G54 (where the CNC tool starts spinning) is amazingly simple but error prone.

The cool thing is that it can be simulated, proofed before you click on the CNC’s go button…

I learned how to make different boards center dowel work - but it’s complicated to make it easy… I have to machine the offset shims to a true center and a xy0 positions opposite of the G54 - Guitar is always carved at the bottom of the wood block (from the top).

Optimizing the process is not as easy as I thought… Went from 20 minutes all carved out to 1 hour + setup time (and flip times)… BTW, got a new guitar blue print… Lots of comparisons to make to my references (and those I changed)…

If this looks cool, you have to google guitar design and click in images to find the wildest variety of a product that can be made. Local Luthiers are in a trip of their own and cant find time to help - like im busy building a guitar and digging my own cave…

I do have a deadline so this ends in June officially as I deliver the first guitar… So glad full body guitars dont give a hoot about cavities…

Not that I am not going to give up in giving this guitar a non-flat surface treatment before it’s over!

Im thinking about sub-d bubble like spacewarp guitars next with galapagos tuned cavities! Might help LOL…

So first carving…

The shoe box already went into the board for a pocket (the control box which is the deepest! NP, I will 3D print another (when i get a new 3D printer that works).

Quite a few points to talk about at this point… The controlbox depth and the dust extractor shoe-box colliging (change in program).

The board can flattened (2 weeks ago) and the guitar body sits inside (middle z) of the block.

So Im really surprized that parts of the guitar are not below the top line. No I didn’t measure… I wanted to flatten first and decided against it because I go so little play between the surface and the model - about 1mm or less. Lesson learned, i’ll made the body thinner…

That’s wood expansion (in mms)…Between the wood block, flat surfaced cnc wasteboard and the model inside…

Bottom line no one cares if the body is 44 or 43 mms but it might be an interesting factor to weight in the balance of the body/neck… Not that poplar wood is that heavy… I will have to measure with the paddauk wood I got in stock once the cnc strategy is fully ready.

This is the most complex cnc job I’ve done so far… Learning each day non-stop!

Finally cut… Perfect edges (except the fillet around the body). Some sanding and chiseling needed but that’s all.

The neck came out too tight, 0.5mms off somehow despite all the previous testing… Maybe I just hammer it down… ![]()

Cheap poplar wood - lots of issues to resolve like not perfect side cuts matching top and bottom curves… etc… For a first cut, prototype, Im happy. I learned a LOT!