Hello all,

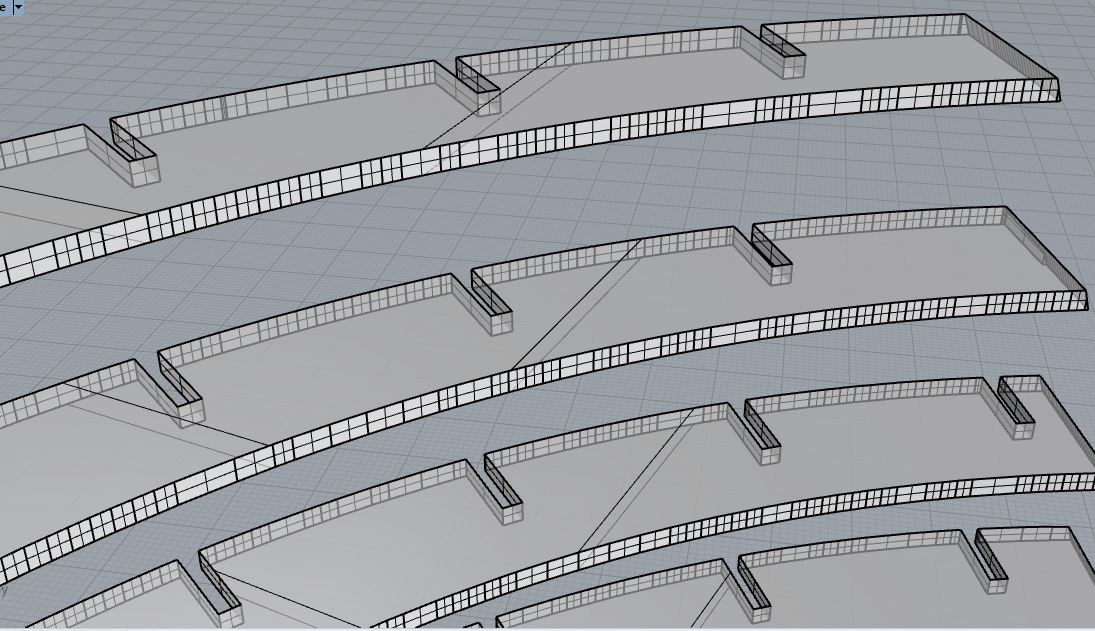

So this is my first solo grasshopper def so bear with me. I’m attempting to bake the final result but the ribs are coming out with low quality. It’s subdividing my curves into large straight lines. I’ve tried to edit the mesh brep setting but I’m having no luck. I’m hoping someone could help.

Thanks!

I think this must be to do with the mesh settings… Bowerbird is getting it’s section curves from taking plane - mesh intersections and the straight lines you are getting are the result of intersecting planar mesh faces with planes.

You could adjust the mesh Brep settings so you get more mesh faces (i.e. a higher quality mesh) but you will still get straight lines, just more, shorter lines.

The only way to get curves would be to explode the section curves and draw curves through the end points but this will probably be a manual or semi - manual process.

1 Like

Thanks Marty for the response. So even if I convert everything to mesh, I will still not have a a nice smooth curve? How do people use Bowerbird and mill with it’s results? I’ve done many manual waffle structures but I was hoping to avoid this by finally getting myself in grasshopper…

Thanks.

If your mesh resolution is high enough you shouldn’t notice the facetting.

When you mill a curve it usually gets translated into g-code lines or arcs anyway!

1 Like

Ohhh thats right. Okay so basically I need to keep everything in mesh mode and I’ll be good to go?

In your opinion what is the most proper way to do complex waffle structures for double curved surface fabrication? Accuracy is very important. I’d like to establish a “go to” def that I can apply to different conditions in the future.

On a side note is there a way to manually move the placement of where bowerbird creates a contour from a mass?

Well Bowerbord can only work from a Mesh input so you kind of have to work with meshes.

There are RSlit and BoxSlit components under the INTERSECT tab but I can never get these to work.

When you convert your Brep to a Mesh, the mesh settings dictate how well the mesh will approximate your Brep. A high quality mesh with very close approximation to the Brep will result in a mesh that has lots of small mesh faces. This will give slices that are polylines made up of lots of small lines. If the lines are small enough you won’t notice the faceting of curves when you CNC machine them.

I have found Bowerbird to be very good for this type of project but I don’t think you can specify exactly where the section planes will be… Bowerbird determines this.

The mesh settings are still low quality after research and setting adjustments. They just wont adjust properly. It’s unfortunate that Bowerbird is in mesh. I’m afraid the mill is still going to pick up each jagged edge. I just need a curved curve to be just that. And at this resolution arcs lines will be very long straight lines. Not sure what I’m missing.

You could try using the RegionSlit component under the Intersect Tab Menu and create your regions using Brep / Plane intersect component.

This is a much more manual process though.

1 Like

Not a bad idea! It’s difficult to find a clean radial waffle def. I’ve seen some very complex real-world rib structures. I’m so curious about how their defs look.

The grasshopper community doesn’t seem as active as it use to be. I wonder why. I guess ppl stopped making waffles in 2015. Or I’m so late to the party, everyone has already left

Ppl out here measuring the reverse polarity of earths magnetic field found in a tree stump from a billion years ago and I can’t solve an automated contour…

I’ll upload a more exciting def and model soon. Hopefully, it’ll stir some excitement.

Yeah, include the def and you’ll likely get more interest for sure.

Bowerbird is a great plugin but not everyone uses it and, like you say, waffles are so 2015!

An updated waffle tool that gives more flexibility on slice plane position and perhaps had more slice layout automation, worked from Breps etc etc would be cool.

1 Like

I changed the name of the topic. Bowerbird is great for smaller projects but when it comes to full-scale fabrication and hardware installation, for me, it was hard to use. Also, I don’t use meshes for fabrication. The mill hates meshes  . Don’t get me wrong, I love Bowerbird. It allowed me to slowly get into grasshopper and I learned very much because of Bowerbirds simplicity.

. Don’t get me wrong, I love Bowerbird. It allowed me to slowly get into grasshopper and I learned very much because of Bowerbirds simplicity.

But I moved on to creating a def for radial breps that gives me a bit more freedom. I’m trying to make it as clean and simple as possible. But since I’m not a grasshopper guru I struggling a bit.

I know its something simple I just can’t figure it out. My brep|brep isn’t evaluating all of the intersections. Also, it seems my origin plans are off a bit and my notches are going in two different directions. I’ve flattening my inputs but that doesn’t help either. And only when they’re not flattened do I get all of my intersections evaluated. But when that happens my planes are doubled in two directions so the notches are the whole length of the rib.

Thanks, fam.

Waffle Rebuild.gh (50.9 KB) Radial Waffle Test.3dm (213.7 KB)

You can use : Region slits and Pufferfish offset surface to create solid

Waffle Rebuild2.gh (49.5 KB)

2 Likes

Seghier,

I keep seeing Pufferfish but have yet to use it. I really appreciate! This seems a hell of a lot easier than what I was doing. I’ll give that a shot in a bit and post the results after added hardware connections etc. I’m curious to see how this compares to bowerbird.

Thanks again.

Let’s say I wanted to add a brep thingy (bracket or tabbing system to attach to a skin) at a giving point and spacing along the boundary of each top and bottom surface of the horizontal and vertical ribs, what would be the smartest approach? Boundary edge, offset, divide curve? And then I’m stuck. Should I open a new topic for this?

Post an image it’s better for understanding

2 Likes

www.food4rhino is under maintenance… and I don’t have Pufferfish

Alright its already back up! So the def seems to work but throwing a “1. shape must be a planar region” code when I apply it to a larger section of the model. Not sure why

Seghier,

It’s come down to the Brep | Plane. For some reason, the vertical plane isn’t following through with its prep frames input. I might start another post for this one. Thanks for the help!

Is this the same shape and the same file?

sometimes you can’ apply the same defintion to different shapes

. Don’t get me wrong, I love Bowerbird. It allowed me to slowly get into grasshopper and I learned very much because of Bowerbirds simplicity.

. Don’t get me wrong, I love Bowerbird. It allowed me to slowly get into grasshopper and I learned very much because of Bowerbirds simplicity.