Hello Rhino community,

I would like to ask for some help regarding the conversion of polysurfaces into SubD objects. My goal is to achieve an organic SubD result without generating elements that are too thin. It doesn’t matter if the holes get deformed during the conversion, as long as the overall design is preserved.

These parts, even if further refined afterwards, must remain suitable for machining. Since I have more than 40 similar pieces to create, I would like to avoid having to redraw each one manually.

Is there a simple workflow or parameter setting that could help me obtain an acceptable SubD conversion directly from polysurfaces, while keeping the geometry machinable?

Thank you very much for your advice !

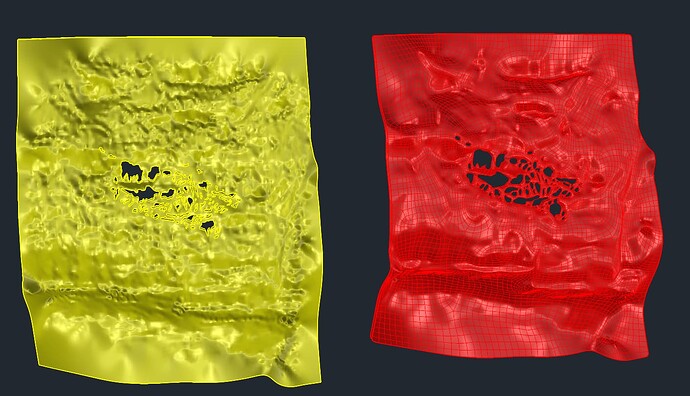

example 1, no acceptable at all :

The conversion (yellow = polysurface / red = sub d) above gives the desired design but creates geometries that are too thin.

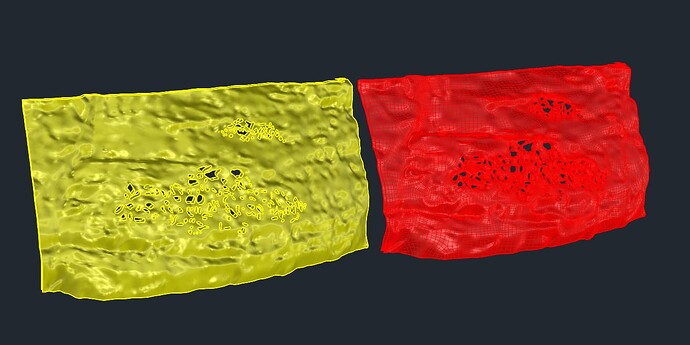

example 2, a bit more acceptable :

Attached below are the 3D file containing 6 polysurfaces to be converted into SubD.

3D - POLYSRF TO SUB D - 6.3dm (3.8 MB)

3D - POLYSRF TO SUB D - 5.3dm (3.5 MB)

3D - POLYSRF TO SUB D - 4.3dm (2.5 MB)

3D - POLYSRF TO SUB D - 3.3dm (2.8 MB)

3D - POLYSRF TO SUB D - 2.3dm (18.6 MB)

3D - POLYSRF TO SUB D - 1.3dm (2.8 MB)