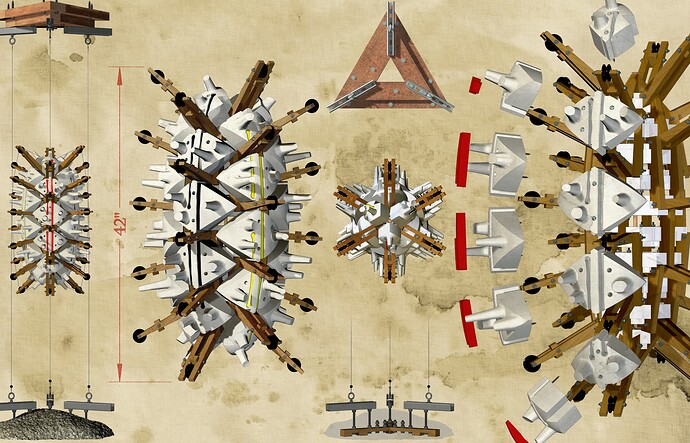

This is a project from 2018 (so: begun using Rhino 5 and finished with Rhino 6), a followup to a related 2014 sculptural experiment in 3D printing and craft described here in the Rhino 3D galleries. There is a similar procedural operation (based on projections of a pair of equilateral triangles onto the surface of an enclosing ellipsoid) generating the form. The projecting organic “kite” shapes were to be 3D printed, or made using a vacuum-formed mold derived from 3D prints, supported by a hardwood framework locked into position by another set of (largely hidden) 3D-printed forms. Off-the-shelf hardware such as pulleys, mounts, and steel cable were sourced from McMaster-Carr.

The spikey structure was designed to hang in midair, on a complicated looping and tensioned trio of steel cables, and the height at which it was suspended could be controlled by the spacing between the eyebolts in the floor and ceiling mounts…or at least the process seemed to work with some tiny models I whipped up in my workshop.

For a working title for this assembly I used the Tibetan phrase Rigsum Gonpo, which is of course the term for the Three Protectors of Himalayan Buddhism, the bodhisattvas Avalokiteshvara, Manjushri and Vajrapani. I had been studying Himalayan Cultural Region (“HCR”) traditional architecture as well as traveling in Bhutan when I first developed this project, and I had been impressed with the way these supernatural beings were represented and invoked on various structures and natural features with poured paint in their specific symbolic colors. The organic kite shapes for my piece included simulated “dripping paint”: inlaid, colored 3D prints.

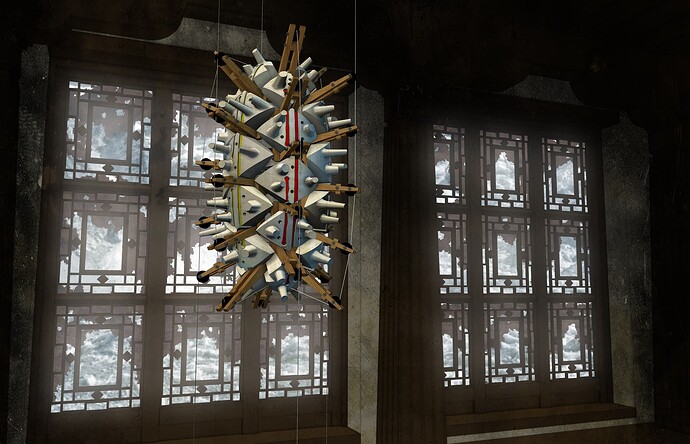

I also created in Rhino a sort of generic HCR architectural environment for “water-color-ish” renderings of what I expected of the finished sculpture, should I ever complete it.

But I never did. I had all the hardware sourced, as noted, and I knew I could print the spiky organic kite shapes as well as the supports for the wooden framework. But I realized I didn’t have the facilities to prepare those wood pieces: there are 132 of them, and they have to be precisely cut and drilled to an accuracy of at least 1/32”, well beyond my own capabilities as a carpenter with the power tools in my workshop. So I would have to find someone who could do it, or most likely someone with a CNC mill (or a water-jet, or an industrial laser cutter, or some digitally-controlled cutting system). And this looked to be an extremely expensive proposition, for a self-directed and non-commissioned bit of experimentation

So the design never went past the Rhino models and these renderings of them…except that I decided I liked the piece enough to put it on my Chinese language business card (我会说汉语), where no doubt it has served me well in protecting me from commissions from anyone with whom I happened to leave it.