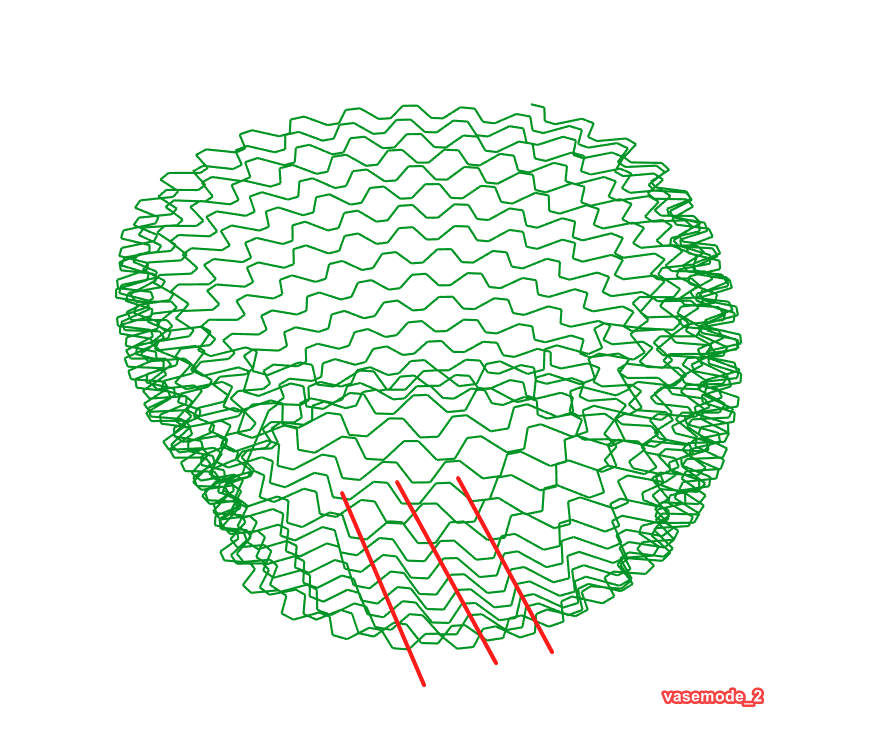

Thanks! Though the pattern is more complex than just normal “zig zag”, I am afaid: I takes the previous layer into account and optimizes the position of the “zigs” and “zags” to keep a nice grid:

this I want to avoid:

edit: if someone is interested I can post the definition, I will anyway but when it actually works