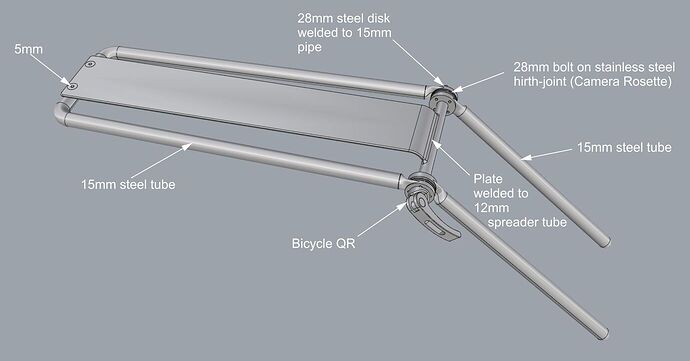

First off, I am not an engineer. I usually design fake architecture made out of wood. That said, I’m attempting this as a Rhino Covid lockdown project I hope to build. It is a custom rack for an ICE Sprint X trike.

My questions for the knowledgeable engineering types:

- Will a 28mm (or 31.8) Hirth-joint hold a load of 0-15lbs spread along the flat horizontal direction assuming the opposite supports are securely fastened? the joints are available in aluminum and stainless steel?

- Assuming the joint will hold, would that weight over the 400mm length of 15mm tube be too flexy or have other problems?

- These Hirth-joints usually have springs in them to push apart when released. (not in the model) However, I’m not sure how strong they are. Does it make sense that the U frame be 2mm or so wider then the assembly and the QR will pull it all together, or might 15mm tube be to inflexible for 2mm give?

- What if I did it out of Carbon Fiber using the same Hirths?

I believe there is software (SolidWorks?) were the details can be plugged in and get such answers. Rhino plugin perhaps?

If anyone has a suggestion for some other rotating adjustable joint in a similar scale that can tighten quickly please do. In fact, this joint sets 6 degree increments. I’d love if there were no need for teeth or detents.

If it’s wrong of me to ask for this kind of help on the forum, mods please remove the post.

RACK_Hirth.3dm (15.9 MB)