Quick way to delete a fillet off a solid?

Hi Paul- there really is not one - if filleting is a finishing up operation, it is best is to keep an unfilleted copy in case you need to make changes.

-Pascal

Oh to have the fillet version of UnTrim…

When I’ve not done as Pascal recommends (saving out a copy) I have resorted to: sub-selecting the fillet(s) using ctrl+shift, deleting them, and extending and retrimming the extended surfaces.

I wouldn’t describe this workaround as quick necessarily, but in a pinch…

d

@pascal - just an idea to script something like an Unfillet-Script when there is an option to detect fillets via the perfect curvature? I know there was a script for Modo for unbevel…

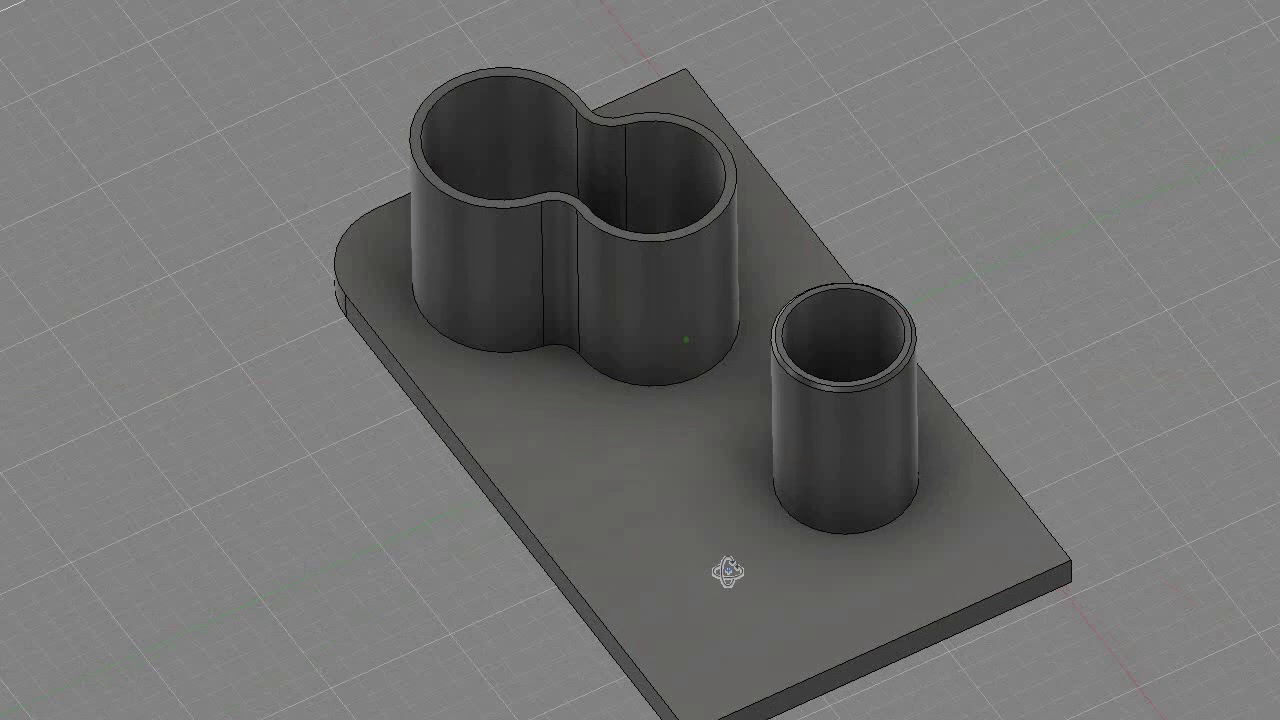

Here is the Modo way

Probably just better to wait for V6… V6 will have partial history on fillets… --Mitch

cool!!!

5 years later… still no solution for this? Not even on a custom script level?

I’m all for picking individual fillets (and in the correct order of overlap) if it can’t be made fully automatic, as long as I don’t have to explode, untrim, extend, trim, join…

I see Modo as an example above, and I know that mesh editing is quite different from nurbs editing, but there’s a recent example for Blender as well:

It’s got amazing options for detecting even variable width fillets and options for face results after the unbevel operation.

It’s not really possible to keep a copy of data you didn’t create. Lots of times we get an assembly and we’re only working on a few pieces.

Also, Fusion360 can do it.  Although, they have other issues, like…in order to do you it, you have to manually select every single piece, One at a time. And they never caught on to the drag box select like Rhino has. No Alt key selection drag to avoid dragging things.

Although, they have other issues, like…in order to do you it, you have to manually select every single piece, One at a time. And they never caught on to the drag box select like Rhino has. No Alt key selection drag to avoid dragging things.

Although, Rhino could still be improved there. Select one part of a fillet, hold a modifier key and select another one a few surfaces away and it could select the surfaces between using a defined method like, say a shared edge and another shared edge endpoint? So similar to chain. But something more like, select faces between the last selected using the most direct path.

Fusion also changes (and sometimes messes up) the control point structure of surfaces when you de-feature breps/solids/bodies.

Everyone (including me) has only posted polygon software examples of this “wishful thinking” feature so far… but we’re currently trialing a CAD software at work that actually has this, and it’s god damn magical (and that’s not even a fillet I’m removing there, that’s a G2 loft made in Rhino):

But yes, the cost of this software is absolutely insane (and it comes with zero ownership, only rent)… still, I re-iterate that I would happily pay double the cost of Rhino for this feature alone!

EDIT: Oh, and yeah… you can make it fail, haha… but a neat list with reasons why it fails appear…

Lots of different CAD software at different price points do defeaturing.

Basically all of the direct-modeling type of CAD.

Nothing I’ve used up until now has worked this well, though… I mean, this is basically “untrim” for solids:

I did not know that. I also replaced my example above with a more advanced one (a lofted surface) and actually Fusion 360 managed to delete it as well with no issue… damn, Rhino is really behind in this area, even more than I thought.

I used to daily work with CAD not capable of doing it these things as well. And from time to time I wished to have a better solution. However, in most cases reversing the theoretical shape wasn’t a big deal at all. Filleting is a postprocess, so even if I wasn’t the creator or for some reason I had no copy of the unfillet state (which I always keep), reversing usually takes just a very short time. The problem I saw with those automation tools, is that they may add spans or unnecessary complexity to it. I don’t have a solution for that, but I just like to say that I frequently create copies of a shape before I start to fillet or before I do any other complex modification for exactly this reason.

Yeah, but “work how we want you to” is never a really great way to solve problems. For CAD software, telling that to an engineer might fly, but telling that to an industrial designer or other person considered a fine artist, less likely.

The reason we are using Rhino is speed. I can quickly hack together what I need, faster than what is possible with solid modeling. For me, I can edit other people’s engineering data just enough in Rhino…usually. It’s faster than fusion for many things. Opening a step file is Not one of them. But reorganizing that step file into layers instead of an insanely useless (unless you’re Really familiar with the model) model tree, Rhino is Much faster. But if I need to defeature something, no, Rhino Definitely loses there. I’ll throw that part over to Fusion 360 to handle.

About worrying about complexity…Don’t. Fusion is actually changing your model a bit. You’ll be surprised to find that it changed the shape more than you wanted in some cases. But chances are, if you’re defeaturing, it’s because you’re hoping to make some changes anyway.

And in Rhino, the only way to do complex shapes, is to explode the whole thing. Delete all your fillets/chamfers, untrim all those shapes, then use extend surface for shapes that don’t end up intersecting. And if it’s really complex, you won’t be able to just use “create solid” so you’ll have an endless amount of trims to do by hand. That’s never fun.

Fusion’s solution is definitley not perfect, but decent.

100% this.

Slightly “adjusted” surfaces adding control points and spans seems to be the price to pay for these direct modeling features.

For more “engineering-type” objects this is perfectly fine.

For high quality surfacing, not so much.

Well, if you’re doing fillets with the fillet tool in Rhino, you’re not really ending up with high quality surfacing anyway, are you? I could be wrong, but I thought fillets were limited to degree2. Wouldn’t that always give you a continuity break?

Defeaturing, would change the surface a bit, but in the case of what Fusion does, it changes because it ends up rebuilding the surface. So it changes the shape slightly, but that doesn’t mean it’s a bad surface. If you Don’t change the shape slightly, it’s likely a “bad” surface because it then would have uneven spans. At that point, you should likely rebuild the surface. But in Rhino you can’t really rebuild a trimmed surface? That’s a question, not assumption. I’m just to learn how people are dealing with this sort of thing. I’d rather not have to jump to another software, completely rebuilt, or Hack the model together.

Often times, we’re redesigning Part of existing data. You don’t want to change some of it, but don’t have time to rebuilt the entire thing. So then you just have to sort of hack it all together and it’s never pretty. But if you can defeature bits here and there, you can save quite a bit of time.

It all depends on the dimensions of fillets obviously.

And there are edgeblends too.

Wow, how I did miss that command all this time!?

Those do Not make very good boundary connections though. I mean, yikes, that’s some nasty surfacing.

Next you’re going to tell me Rhino can do Y shaped connections instead of boundaries without you having to manually build them.