Hi Kyle,

Thank you for the interest.

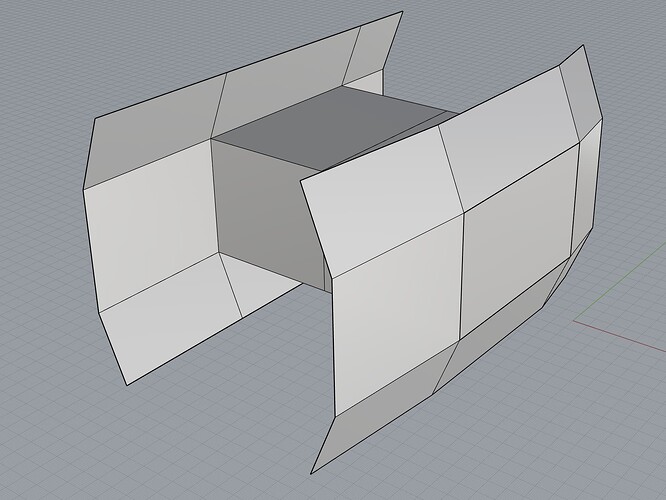

I am trying to create an opening without affecting the curvature of the outer panel. Sorry, about my quickie example.

I’ve been working on an aerodynamic vehicle body using Rhino SubD, having done eleven generations of OpenFoam study, and work on aesthetics, which was needed.

As similar technique as NURB’s, there are very few control nodes in the shell, as few as possible, which allows the shape to optimized–without extraneous intermediate nodes which would only degrade the the shape.

In parallel, I also studying the vehicle frame/chassis. It’s not as far along because of the question of process and materials, but also, it’s not as far along because my computer model cannot complain, so a real-world mock-up is necessary.

Also, in parallel, I have been roughing out the interior.

So…

I want to be able to cut door and window openings and into the vehicle body–without affecting the larger sense of its shape.

I also like the technique of matching the dash to the hoodline, which is not always done.

I have a sense of how to make the body out of NURB’s, but once they are trimmed and joined, that hull could not be easily re-proportioned, as to say, make the window opening a bit smaller. I would need to maintain several stages of body surfaces and primitives, also.

Presently, it’s in SubD, if I add nodes to add window openings, the face splits they would cause would make it difficult to keep the exterior shape. Rhino is very forgiving by adding and maintaining hidden splits, but for a big hole, more car body surface nodes would need to be added, and because of that, changing the the surface would be less accurate. Smoothing might then help, but presently, we cannot smooth to a guide spline, which I have been doing manually ; )

[ Basically, weather I have a SubD or NURB surface/curve with say 5 nodes, I use a 3-node curve as a guide to attempt to fair the more complicated surface/curve the same as the the more simple one.]

The problem for either SubD or NURB is: once cut, the more complex resultant object cannot be re-proportioned as well as a lesser node variety.

~

If we could do this, it would have two advantages.

1.) You could more easily make something like a Porsche 911, Americana, and Cayenne from the same geometry.

2.) It would allow body/interior/chassis to be developed in parallel more easily. (My application)

3.) It would allow styling updates and engineering changes to happen with fewer problems, such as the vehicle’s hood now has to come down lower to meet anti-pedestrian rules, or American ground clearance heights, or whatever fanciful things they have planned for the Euro 6,7,8.

~

It would seem that two things would be required/helpful to make this happen.

1.) The ability to hide SubD faces, so they can be part of the shape solution, such as NURB trims retain the original shape.

2.) The ability to intersect SubD’s using a hierarchy, and let us go back to the original shape. This would also be handy for NURBs, too. For this purpose, the thing is that somehow, the later subtractions cannot affect the original shape.

[I usually keep an Home-Depot orange Tool layer just for tools, but I also keep layers of each boolean-step. Managing this would be more fun, with just a right-click menu. I like the way 2d programs make compound objects. The metaphor of Rhino’s multiple undo would be good thing to start from, but let us do booleans like this, too.]

Using another metaphor, we would be making T-SubD’s.