This is my 2022 Bachelor Thesis for Bachelor of Arts in Fashion & Technology at kunstuni-linz.at, link

Check out the website for this project: liquidsneaker.com

In 2017, MIT‘s Self-Assembly Lab published „Large-Scale Rapid Liquid Printig“, outlining a new manufacturing method for liquid, curable materials. Depositing the liquid into a thick, clear gel, the material stays in place and cures, either over time of through ultra violet light. This is an entirely new manufacturing method for many industrial grade materials, that previously relied on Injection moulding.

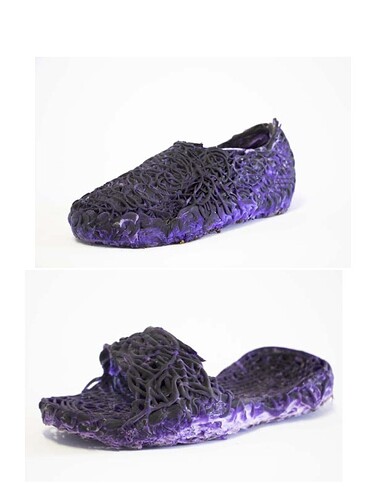

This new technology is not only exciting for industry, but especially for creatives and small studios, allowing prototyping and manufactuing at small scales. This project explores the application of this technology to sneakers. It is a highly relevant field, because the market is currently only accessible through mass production, and independent designers rely entirely on collaborations. The same high performance footwear materials used today can be applied to this technology, making it a perfect match for unlocking explosive potential in the field.

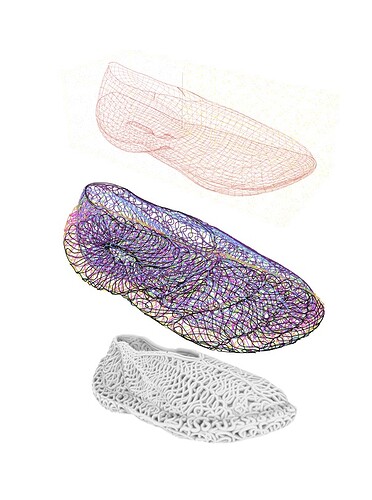

Because liquid printing works radicaly different from other manufacting methods, it also opens a space for new design strategies. As part of this project, a workflow was implemented that translates intuitive drawing in 3D space to movements of the printing nozzle within the gel. This creates a blurry boundary between the physical and the file, where real movements create real objects through a digital bridge formed from Virtual Reality and industrial robotics.

Follow my exploration through the stages of setting up the technology, test printing, developing an unprecedented design strategy and executing it through wearable prototypes.

This is a pneumatic cartridge extruder. Air pressure activated two pistons that extrude a 2:1, two component material cartridge into a static mixing nozzle. A needle with a diameter of 2mm is attached to the mixer.

The six-axis industrial robot follows a toolpath with the tip of the extruder. In addition to the curve, it can also vary the orientation of the tool. This sets it apart from three axis systems and allows for greater complexity.

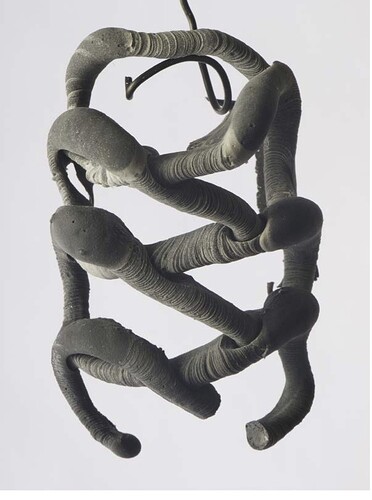

Some test prints for different Liquid printed structures: polyurethane printed into a carrying hydrogel.

Check out the website for this project: liquidsneaker.com