Well, I am finishing my naval engineering course (it is a mix between marine engineering and naval architecture) and I heard since day one of my course how I should practice and get comfortable with Rhino because all shipyards use it and stuff.

I was starting to do so, but I got an internship in the college engineering department and they used Solidworks heavily, so I focused on getting good on what I was using, but I always kept thinking about Rhino, then that internship ended 2 years later>

I was about to seek the rhino training again but I got selected for a scientific initiation program, basically its an internship to learn how the researching side of the college works to see if I would like it and seek an masters to become teacher or something, I did heavy programming in Pascal/Delphi, some C++ and Python for another year and a half and Rhino got left behind again, that ended as well

I was in need of money, so applied for an internship on the IT department where I did a lot of user support and also, given my programming knowledge, helped with some internal system stuff, for another year, and Rhino got left behind again.

Finally I was in last year and I got an internship in a Shipyard, and had a month of extensive Rhino modelling with all tutorials I could get to get ready for it, and I loved using Rhino with all my passion, It was a bumpy ride, but was 100x more enjoyable and stress free than using surfacing inside solid (it get the job done but… with a heavy price in sanity, IMO) and since all my teachers said it was absolutely, I was thrilled to start working in the shipyard.

When I started it, they were using mostly Solidworks (in a so wrong and messy workflow that is hard to even describe, to this day I still have nightmares with missing references and tree error from start to finish in 300 ish commands list)

I kinda still push the Rhino usage, and one of our third parties use as its main tool, so I am the one receiving all those files.

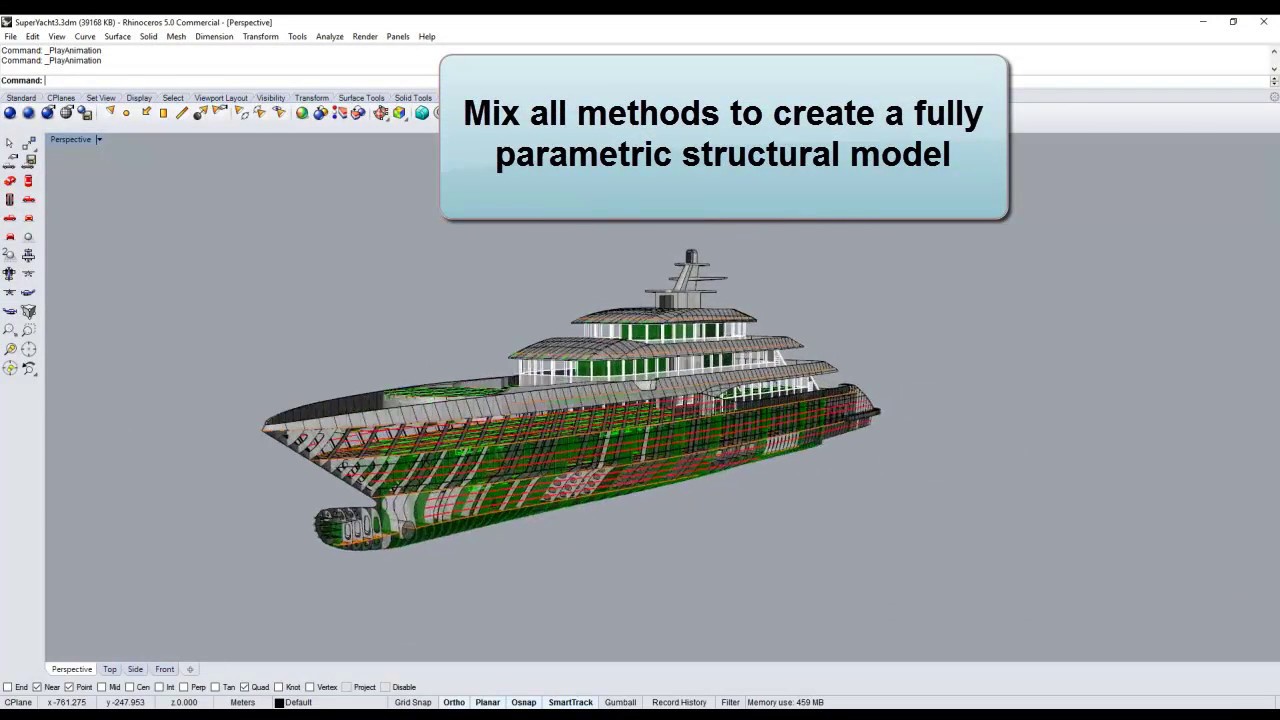

I know Rhino is not suppose to be an engineering tool as other solid modellers sell themselves, but the versatility and robustness is so freaking amazing that I feel dirty using any solid modeller.

I just asked about start to finish, in hope to get some knowledge of some plugin or workflow that really makes rhino shine, I even started using Rhino for document and presentations, using Picture Frame and layers for it (come at me LayerBook).

I am also trying to learn grasshopper to incorporate in my workflow, and also Fologram.

So please, if you, or anyone that reads this, with the amazing experience of these forum users combined, please share your knowledge with us, new(ish)comers.